Optical Surfaces Ltd has developed a new method to test the Modulation Transfer Function (MTF) of large aperture military optical systems using a series of pre-aligned beam assemblies.

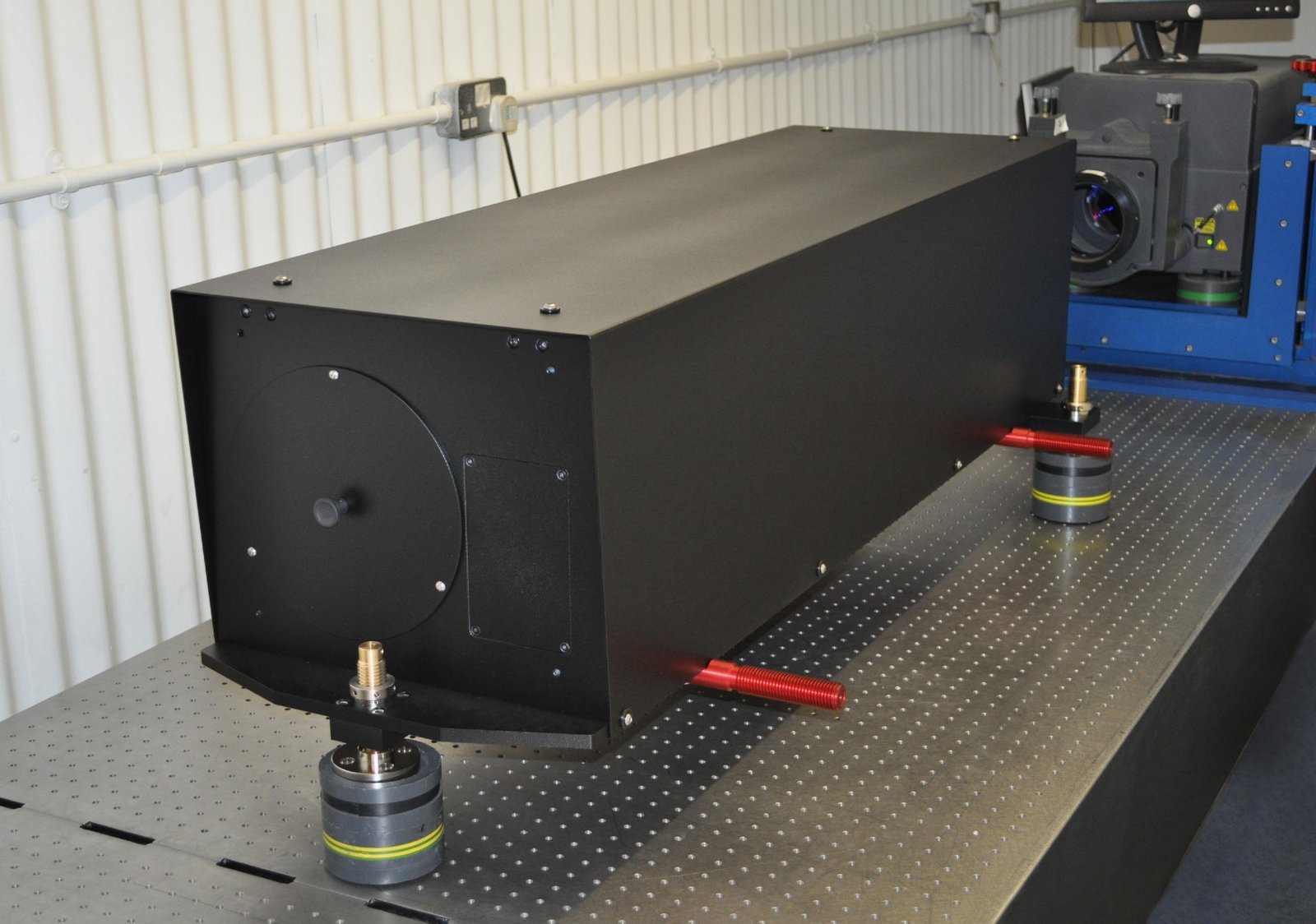

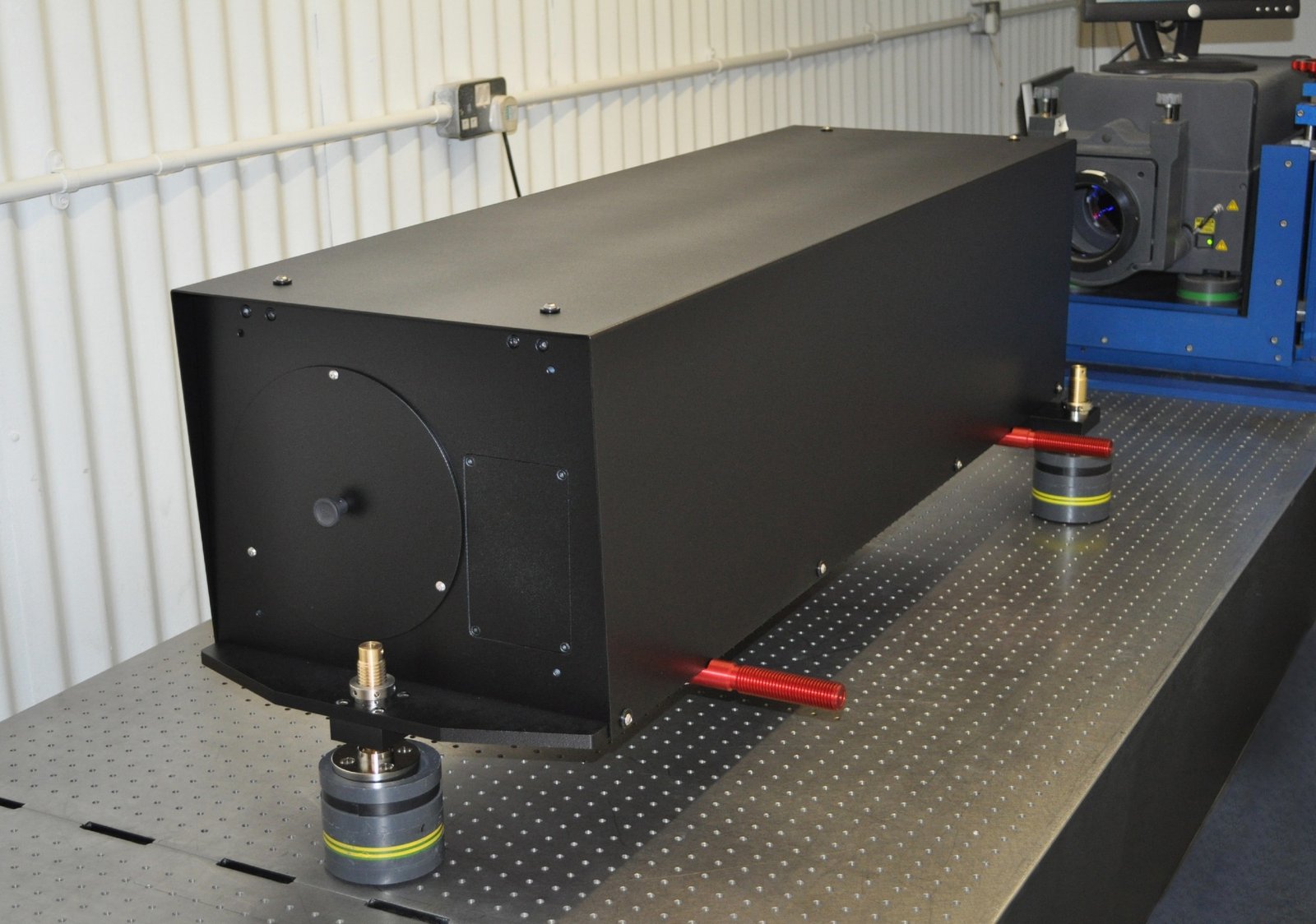

The 250mm aperture (1.5m focal length) beam collimation system is fully assembled on an optical table. Image courtesy of Optical Surfaces Ltd.

MTF is a technique relied upon by optical designers to objectively evaluate the imaging capabilities of military optical systems. Reflected beam collimators are the perfect instrument to perform MTF measurements because they can be used to replicate targets at infinity or intermediate distances without parallax .

However, testing larger diameter military optical systems (>250mm) or needing an MTF system that provides longer focal length focusing capabilities traditionally requires very large, heavy and expensive reflective beam collimator systems.

“Based on decades of experience in manufacturing high performance reflective beam collimators, our R&D team has devised a new way to address this challenge,” comments Dr. Aris Kouris of Optical Surfaces Ltd. We can now supply large collimators as sub-assemblies consisting of a mounted off-axis parabolic mirror and a mounted folding plane, which are easily assembled directly onto a standard optical table. Supplied pre-aligned in our manufacturing test facility, precision alignment tools are available during assembly to quickly and accurately find the focal plane and centre of field of view. If required, we can also provide a protective cap that fits over the assembled beam collimation system.

With their compact and lightweight design, Optical Surfaces beam collimators uniquely combine high stability and high performance making them an excellent solution for testing military optical systems with large diameters or long focal lengths.

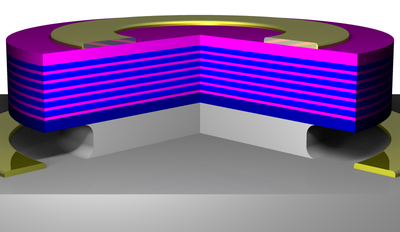

The high stability and performance of these new reflective beam collimators is achieved by using non-expanded parabolic mirrors manufactured with a surface accuracy better than lambda/10 pv. The off-axis design of the Optical Surface Module beam collimators ensures no central blockage and highly efficient transmission. The fully reflective design of these beam collimators is achromatic, and the aluminum/magnesium fluoride coating allows them to operate from UV to IR without adjustment.

For more information about beam collimators for testing military optical systems, contact Optical Surfaces Ltd. at[email protected] .

Optical Surfaces Ltd has been manufacturing high precision optical components and systems for almost 60 years. Their ISO 9001-2015 certified manufacturing and testing facilities are located in tunnels bored deep into the solid Late Cretaceous Earth, providing a constant temperature and virtually vibration-free environment. These stable conditions mean that testing, especially over long paths, is quantifiable and reliable.