In a study published in the journal Light: Science & Applications , a team of researchers from JSR Corporation and the University of Tokyo created and tested a flat lens called a Fresnel zone plate (FZP), the first to be adapted specifically for an i-line stepper, a type of equipment often used in semiconductor manufacturing.

Paper-thin optical lenses, which can be mass-produced as easily as microchips, could enable a new generation of miniature optical devices.

Although current flat lenses are not as efficient as manufactured lenses, they have the potential to transform optics in many industries, including astronomy, medicine and electronics.

Although flat lenses, such as metallic lenses, exist, they are expensive, complex, and have limited equipment availability. To improve the quality, performance, and efficiency of equipment while reducing costs, manufacturers are exploring alternatives through academic research. FZP has emerged as a promising option to improve optical systems that require a small footprint. For the first time, researchers have prototyped a lens in just a few simple steps using industry-standard techniques.

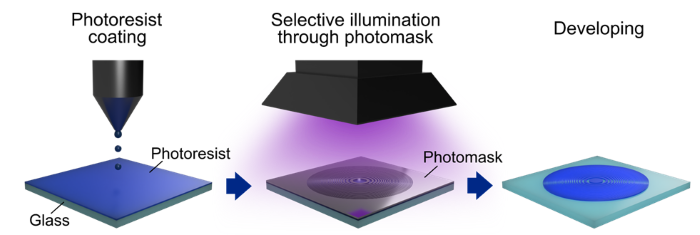

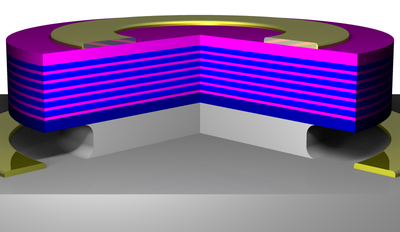

Using conventional or stepper semiconductor photolithography systems, we have developed a simple, mass-producible method of producing FZPs using a special type of photoresist or mask, called a color resist, originally designed for use as a color filter. By simply coating, exposing, and coating this material, we have produced lenses capable of focusing visible light down to just 1.1 microns, about 100 times thinner than a human hair.

Kuniaki Konishi, Associate Professor at the Institute for Photonic Quantum Science

A current challenge with the new FZP is that its light-collection efficiency is only 7%, resulting in noisy images. But the team is now aiming to improve it by a factor of four by changing the way they use the resist. This will require greater control over the physical properties of the resist than was available to the researchers at the time of the study, but it can be done.

“In addition to efficiently manufacturing the FZP, we also designed it in simulations that confirmed very good agreement with experiments,” Konishi added. This means that we can customize the design for specific applications in different fields, such as medicine, before we begin manufacturing.”

” Furthermore, unlike conventional manufacturing methods, the FZP manufacturing process eliminates the need for toxic etching chemicals and significantly reduces energy consumption, offering potential environmental and economic benefits, ” he added.

It may be a while before FZP can help you capture moments with high visual fidelity using ultra-thin smartphones, but the technology, or technologies inspired by it, is likely coming soon.

Journal References:

Yamada, R. et al. (2025) Optical Fresnel Zone Flat Plate Lens Made Only with Color Photoresist Using an i-Line Stepper. Light: Science and Applications . doi.org/10.1038/s41377-024-01725-6